In the fast-paced, precision-driven world of chemical manufacturing, reliable motor systems are the heartbeat of operations. From mixing and metering to pumping and conveying, motors drive essential processes that must perform flawlessly under pressure. At Eagle Electric, we specialize in providing industrial motor repair and high-performance new motors specifically tailored to meet the demanding needs of the chemical industry.

Challenges Facing Motor Systems in Chemical Plants

Chemical facilities operate in some of the most challenging industrial environments. Their motor systems are expected to perform 24/7 under high temperatures, corrosive conditions, and strict safety protocols. These challenges include:

- Excessive wear and tear due to continuous operation.

- Risk of motor failure, leading to costly production downtime.

- Strict compliance requirements for hazardous locations and environmental safety.

To meet these demands, chemical plants need a trusted partner who understands both the technical and regulatory aspects of their operations.

Tailored Motor Solutions for Chemical Manufacturers

Eagle Electric offers specialized solutions that keep chemical production running smoothly:

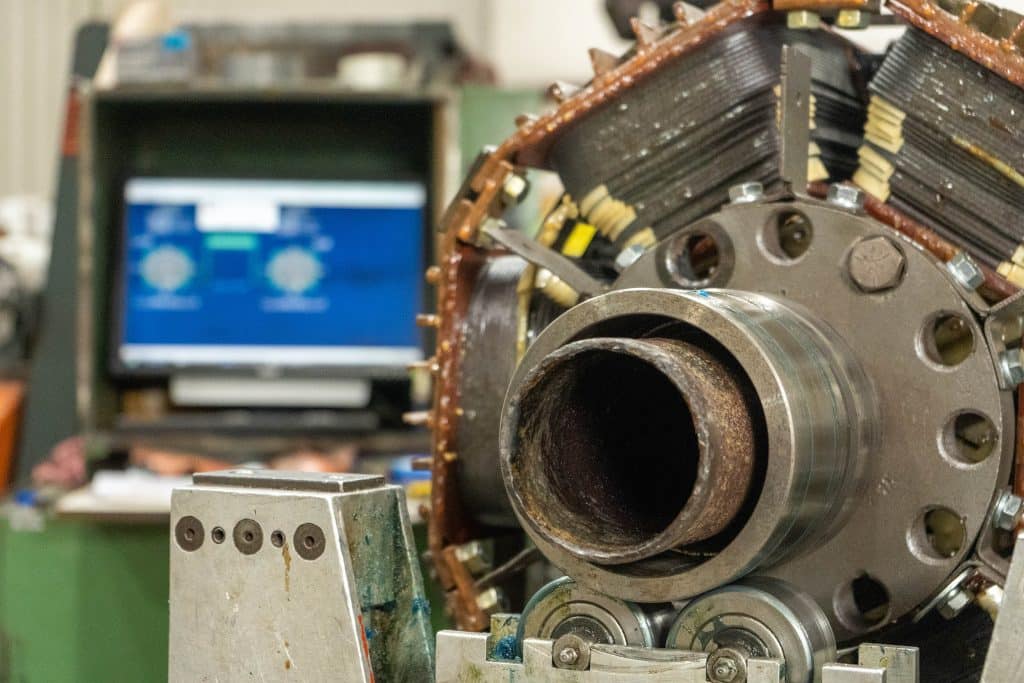

Industrial Motor Repair Services

- Skilled repair of motors exposed to corrosive and hazardous environments.

- Comprehensive diagnostics, rewinding, bearing replacement, and component repairs.

- In-shop and on-site service capabilities to minimize plant disruptions.

We provide a broad range of motors designed for the chemical sector, including:

- Explosion-proof motors ideal for Class I and II hazardous environments.

- High-efficiency motors that help reduce energy consumption and operational costs.

- Pump and agitator motors designed for precision mixing and fluid movement.

Why Reliable Motors Are Critical in the Chemical Sector

Investing in quality motors is more than a matter of performance—it’s a matter of safety and efficiency. High-performance motors are essential for:

- Ensuring safety in explosive or chemically reactive environments.

- Maintaining uptime, keeping production on schedule and minimizing financial losses.

- Supporting precision operations, including batching, blending, and dosing.

Types of Motors Offered for Chemical Applications

Eagle Electric’s catalog includes:

- AC and DC motors tailored to specific process needs.

- Explosion-proof and washdown-duty motors designed for harsh or wet environments.

- Custom-configured motor solutions for unique chemical processing applications.

Expert Motor Repair for the Chemical Industry

Our team of certified technicians excels in:

- Repairing windings, bearings, insulation systems, and seals.

- Rebuilding motors to meet or exceed OEM performance standards.

- Servicing motors from top industry brands trusted in chemical manufacturing.

The Eagle Electric Advantage

Partnering with Eagle Electric offers chemical manufacturers several critical benefits:

- Fast turnaround times to reduce costly downtime.

- Access to premium new motors designed for chemical and hazardous applications.

- Enhanced energy efficiency and safety compliance with expertly maintained systems.

Maintenance and After-Sales Support

Our commitment doesn’t end at installation or repair. We offer:

- Preventative maintenance programs to extend motor life.

- Emergency motor repair services, available when you need them most.

- Ongoing technical support and system optimization for peak performance.

Compliant with Chemical Industry Standards

We ensure full compliance with all applicable standards and regulations:

- Hazardous location classifications (Class I, Division 1 & 2; Class II).

- NEMA, IEC, and ATEX standards for safety and environmental protection.

- Deep expertise in motors designed for corrosive and explosive environments.

Why Choose Eagle Electric?

We’ve built our reputation by serving chemical manufacturers with:

- Years of hands-on experience in chemical plant motor solutions.

- Cutting-edge motor technologies and advanced diagnostic tools.

- A proven track record of improving reliability and reducing downtime in critical systems.

Powering Chemical Processes with Confidence

At Eagle Electric, we understand the stakes are high in chemical manufacturing. That’s why we’re committed to delivering durable, efficient, and safety-compliant motor solutions you can depend on. Whether you’re looking for expert motor repair, new motor installation, or ongoing maintenance, we have the tools, knowledge, and dedication to support your success.

Contact Eagle Electric today to discuss your motor needs and see how we can help keep your operations running safely and efficiently.